History

History Showroom Tour

Showroom Tour About The Furniture

About The Furniture Testimonials

Testimonials

Rosewood Furniture: The Process

China Furniture and Arts has been creating authentic rosewood furniture for over 50 years. Techniques dating to the Ming Dynasty in China, combined with modern technology are used in its production today to control both quality and cost.

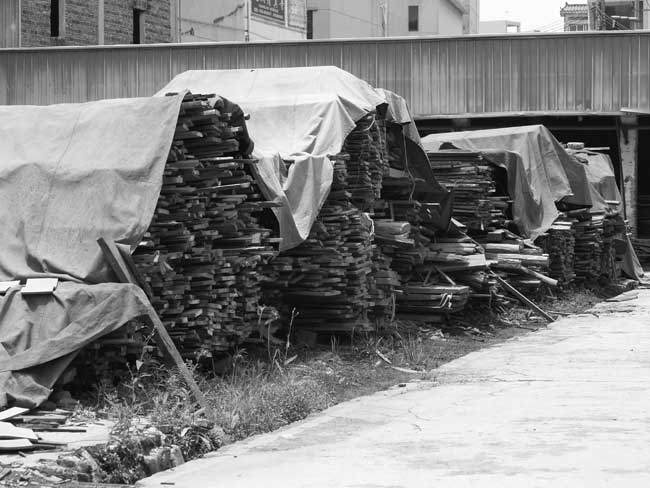

Lumber

The process begins with the selection of the highest quality rosewood. Our wood is imported from Indonesia, Thailand, Laos, and other parts of South East Asia. Large logs are cut into smaller, more easily manageable pieces by a large saw. The wood is then moved to a kiln where it is dried in controlled conditions.

Kilns

Kilns control the three most important factors in the production of quality cured wood: humidity, temperature, and airflow over its surface. Lumber is put into the kiln for weeks to months depending on the condition of the wood and type of wood. By curing, or drying the wood to a low moisture content, the risk of warping and cracking in the final product will be reduced when changes in the humidity occur. This process becomes especially important when the furniture will be exported and used in a different climate.

Traditionally, the lumber is exposed to the air for an extended period to be considered dried, or cured. However, without using enhanced curing methods, the moisture content in the wood would never reach below the moisture level in the air. Today, our lumber is kiln-dried, allowing control over the final moisture content of the wood.

Shaping

After the lumber has sufficiently dried, the large pieces of lumber are further shaped. Curves and other general features can be sculpted by table saws. Larger wood surfaces are created with several panels, linked by tongue and groove joints. Matching wood grains, therefore, are very important to provide consistency to the finished product. Next, rough edges created by sawing are refined by sanding. A plane can also be used to shave the wood to create a smooth and level surface.

Other Details

Details such as carvings and inlays add depth to wood furniture. Rosewood is extremely difficult to carve due to its high density. Therefore, the skill involved in wood carving make it a highly prized art. Mother of Pearl is also often used as decoration in rosewood furniture. It's iridescent and colorful nature contrasts and complements the rosewood's darker wood finish.

Assembly and Joints

Traditional joinery techniques developed through generations of furniture crafting are used to connect wooden parts. Assembly does not require the use of screws or nails and guarantee long-lasting durability. Methods such as tongue and groove joints are used for large surface areas to help prevent warping or cracking due to expansion and contraction of wood; mortise and tenon joints are used to connect other parts, such as legs and corners. Glue may be applied at the joint before pieces are gently hammered into place to ensure a tight fit.

Staining

Rosewood can be stained to a variety of finish colors. Primer is applied to the furniture's surface to fill in pores and other irregularities in the grain to allow stains and paint to more easily bond with the wood. After the primer has dried, the furniture is hand-sanded. Sanding creates a slightly rough texture on the surface, further helping the stains and polish to adhere to the wood.

Stains are created by mixing basic colors. Stains are hand rubbed into the surface of the wood. To achieve a rich and vibrant finish, the pieces are repeatedly hand-rubbed up to 7 times.

Finishing

Additional sanding and staining is also applied to areas of the piece that is not visible. This finishing step is a unique feature of our manufacturing process and shows our commitment of delivering products of the best quality to our customers. After finishing, products are inspected. Upon passing inspection, they are ready to be packed and shipped. You can view our complete selection of timeless rosewood furnishings here.

SocialMedia